MobileDAS (Data Acquisition System) MD Engineering's process control and automation group has created a new monitoring, control and reporting system specifically designed for service trucks in the oil and gas industry.

Key Features

- Industrial wireless touch screen PC with a simple, easy to use interface

|

|||

System Features Monitor Everything on One Screen - Monitor any number of sensors in real time on the Main Monitor screen

|

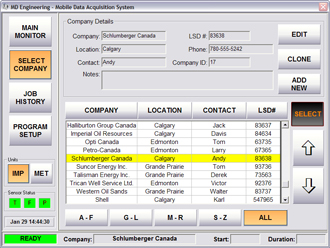

Company Database |

||

- Clone an existing company if you need multiple locations and LSD numbers |

|

||

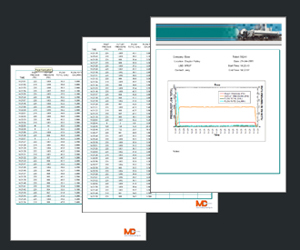

PDF Job Reports - After completing a job, a job report can be created in PDF format and stored on the system hard drive for future reference

|

|

||

|

Job Reports To USB Memory Stick - The job report can also be copied to any USB memory stick with the touch of a button

|

||

Wireless Or Fixed Mount - Touch screen interface can be installed as a fixed mount or wireless unit

|

|

||

Industrial Grade Hardware - Components utilized are built for industrial environments

|

|||

System Benefits Real Time Monitoring - Our system monitors all of the sensors in real time. The operator can watch pressure, temperature, flow and tank level in either numeric or graphical forms. Automatic Safety Shutdowns - Set pressure and temperature alarm limits for shutdown, eliminating expensive failures Industry Leader - State-of-the-art system that is specifically designed for your service truck

- Retrofit existing systems easily - On site or remote support available 24/7 - Options include:

|

|

||

|

|

||

| Copyright © 2009 MD Engineering, All Rights Reserved |